MAZLUM STEEL PIPES

The rock shoe prevents damage to the pile during pile driving in rocky ground.

Outside Diameter : 711,2mm

Wall Thickness : 14,2 mm

Per Pile Length : 25 Meters

BARIŞ TECHNOLOGICAL INSTALLATION

Industrial stacks suitable for solid, liquid, and gaseous fuels, Design and manufacturing in accordance with TS EN 13084, Custom designed solutions for special site and flue conditions, Easy erection due to modular design

BARIŞ TECHNOLOGICAL INSTALLATION

Length is possible up to 12 mt (40 ‘). Easy transportation is available because of the compact frame. Sound insulation is possible at the desired level.Thermal insulation is possible at the desired level

BARIŞ TECHNOLOGICAL INSTALLATION

Deaeration is the process of removing the dissolved oxygen from the boiler feedwater. Additionally, in the deaeration process, the CO2 is also removed. Removal of these two gases is important in

BARIŞ TECHNOLOGICAL INSTALLATION

Cogeneration or combined heat and power (CHP) is the simultaneous production of electricity with the recovery and utilization of waste heat. Cogeneration is a highly efficient form of

MAZLUM STEEL PIPES

Potable Water Pipes with Epoxy Coating. Outside Diameter : 1016mm / Wall Thickness : 10mm / Pipe Length :13.50 Meters / Steel Grade : S355JR

BARIŞ TECHNOLOGICAL INSTALLATION

Ideal solution for plants that need low capacity and quick steam production. Three pass, high efficient steam generators up to 5 t/h steam capacity. Smoke tube and water tube constructions

BARIŞ TECHNOLOGICAL INSTALLATION

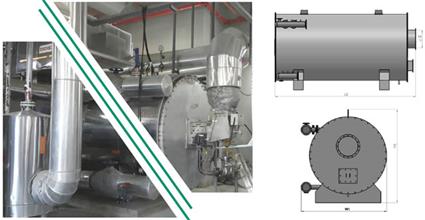

Indirect steam generators can be used instead of a steam boiler in plants where a sufficient heating system exists. Less space requirement due to packaged construction, Low-pressure fluctuations due to large steam and water volume

BARIŞ TECHNOLOGICAL INSTALLATION

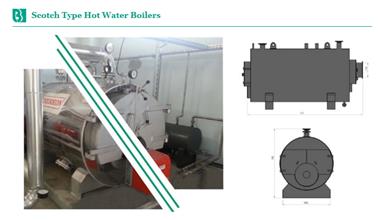

Solid / liquid / gas and biogas fuel options, High efficiency, low thermal losses, Perfect design for optimal heat transfer and flue gas pressure drop, Low NOx formation with 3-pass design and large combustion chamber

BARIŞ TECHNOLOGICAL INSTALLATION

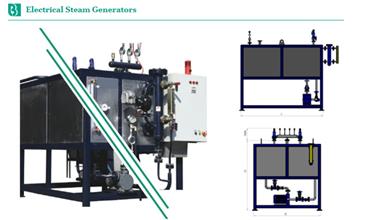

Small-sized, small-capacity ENERKON Electrical Steam Generators are perfect for industries that require quick, efficient, and high-quality steam in laboratories, hospitals..

BARIŞ TECHNOLOGICAL INSTALLATION

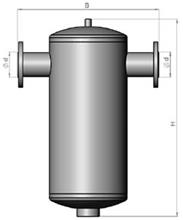

Provides efficient and economical solutions for processes that need dry steam, Provides efficient separation with centrifugal effect, Needs no maintenance due to having no moving part

Withstands unfavorable conditions and water hammer

MAZLUM STEEL PIPES

Internal Sa2 ½ sandblasting. Sandblasting is very neccessary for surface preparation for steel pipes. All surfaces must be thoroughly clean, dry, sound and free from grease, oils, waxes and all loose materials.

BARIŞ TECHNOLOGICAL INSTALLATION

Solid / liquid / gas and biogas fuel options, High efficiency, low thermal losses, Perfect design for optimal heat transfer and oil/flue gas pressure drop

BARIŞ TECHNOLOGICAL INSTALLATION

Solid / liquid / gas and biogas fuel options, High efficiency, low thermal losses, Perfect design for optimal heat transfer and flue gas pressure drop, Low NOx formation with 3-pass design and large combustion