BARIŞ TECHNOLOGİCAL INSTALLATİON

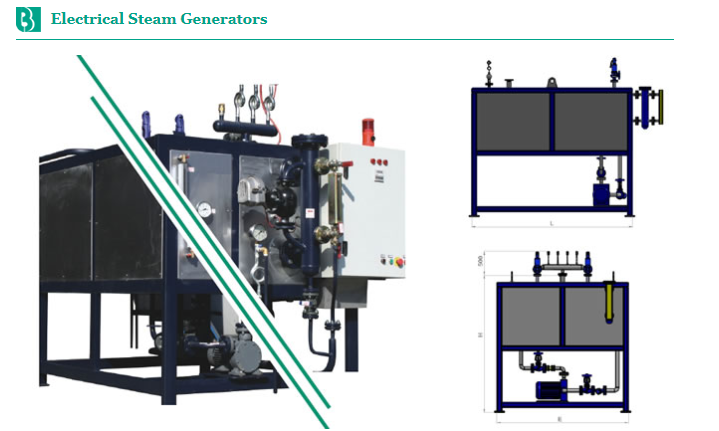

SMOKE TUBE AND WATER TUBE STEAM GENERATORS

Ideal solution for plants that need low capacity and quick steam production. Three pass, high efficient steam generators up to 5 t/h steam capacity. Smoke tube and water tube constructions

MAZLUM STEEL PIPES

QUALITY CONTROL

XRAY and RT Test Line

Hydrostatic Tests

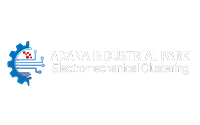

BARIŞ TECHNOLOGİCAL INSTALLATİON

Direct hot water production from cold water, Design and production for oil and gas fuels, Completely hot galvanized or stainess steel production, Seconder heating system is not necessary (Steam, Hot water)

BARIŞ TECHNOLOGİCAL INSTALLATİON

COGENERATION - TRIGENERATION SYSTEMS

Cogeneration or combined heat and power (CHP) is the simultaneous production of electricity with the recovery and utilization of waste heat. Cogeneration is a highly efficient form of

BARIŞ TECHNOLOGİCAL INSTALLATİON

ECONOMIZERS AND AIR PREHEATERS

Engineering according to fuel and application specifications, Perfect design for optimal heat transfer and water/flue gas pressure drop, Delivery with all auxiliary equipments (Optional)

MAZLUM STEEL PIPES

The rock shoe prevents damage to the pile during pile driving in rocky ground.

Outside Diameter : 711,2mm

Wall Thickness : 14,2 mm

Per Pile Length : 25 Meters

MAZLUM STEEL PIPES

Potable Water Pipes with Epoxy Coating. Outside Diameter : 1016mm / Wall Thickness : 10mm / Pipe Length :13.50 Meters / Steel Grade : S355JR

BARIŞ TECHNOLOGİCAL INSTALLATİON

Solid / liquid / gas and biogas fuel options, High efficiency, low thermal losses, Perfect design for optimal heat transfer and flue gas pressure drop, Low NOx formation with 3-pass design and large combustion chamber

BARIŞ TECHNOLOGİCAL INSTALLATİON

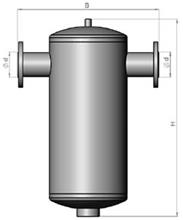

Provides efficient and economical solutions for processes that need dry steam, Provides efficient separation with centrifugal effect, Needs no maintenance due to having no moving part

Withstands unfavorable conditions and water hammer