BARIŞ TECHNOLOGİCAL INSTALLATİON

Deaeration is the process of removing the dissolved oxygen from the boiler feedwater. Additionally, in the deaeration process, the CO2 is also removed. Removal of these two gases is important in

MAZLUM STEEL PIPES

Tubular Piles with Clutch Welding.

Materials : E22 Clutch

Material Steel Grade : API 5L X60 PSL1

Manufacturing Standards : ASTM A252

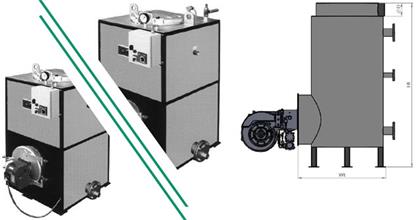

BARIŞ TECHNOLOGİCAL INSTALLATİON

Solid / liquid / gas and biogas fuel options, High efficiency, low thermal losses, Perfect design for optimal heat transfer and flue gas pressure drop, Low NOx formation with 3-pass design and large combustion chamber

BARIŞ TECHNOLOGİCAL INSTALLATİON

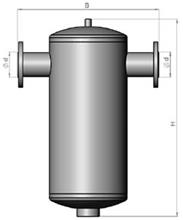

Provides efficient and economical solutions for processes that need dry steam, Provides efficient separation with centrifugal effect, Needs no maintenance due to having no moving part

Withstands unfavorable conditions and water hammer

MAZLUM STEEL PIPES

Potable Water Pipes with Epoxy Coating. Outside Diameter : 1016mm / Wall Thickness : 10mm / Pipe Length :13.50 Meters / Steel Grade : S355JR

BARIŞ TECHNOLOGİCAL INSTALLATİON

Direct hot water production from cold water, Design and production for oil and gas fuels, Completely hot galvanized or stainess steel production, Seconder heating system is not necessary (Steam, Hot water)

BARIŞ TECHNOLOGİCAL INSTALLATİON

Waste heat boilers for hot water, Steam, Superheated steam, Thermal oil, and hot air production, Smoketube and watertube constructions, Custom designed solutions according to waste heat and site conditions

BARIŞ TECHNOLOGİCAL INSTALLATİON

Industrial stacks suitable for solid, liquid, and gaseous fuels, Design and manufacturing in accordance with TS EN 13084, Custom designed solutions for special site and flue conditions, Easy erection due to modular design

ÖNER SEPARATOR

TECNOLOGICAL ONE TOUCH A DESING SOLUTION

TECNOLOGICAL ONE TOUCH A DESING SOLUTION