MAZLUM STEEL PIPES

Tubular Piles with Clutch Welding.

Materials : E22 Clutch

Material Steel Grade : API 5L X60 PSL1

Manufacturing Standards : ASTM A252

BARIŞ TECHNOLOGİCAL INSTALLATİON

Length is possible up to 12 mt (40 ‘). Easy transportation is available because of the compact frame. Sound insulation is possible at the desired level.Thermal insulation is possible at the desired level

ÖNER SEPARATOR

TECNOLOGICAL ONE TOUCH A DESING SOLUTION

TECNOLOGICAL ONE TOUCH A DESING SOLUTION

BARIŞ TECHNOLOGİCAL INSTALLATİON

ECONOMIZERS AND AIR PREHEATERS

Engineering according to fuel and application specifications, Perfect design for optimal heat transfer and water/flue gas pressure drop, Delivery with all auxiliary equipments (Optional)

ÖNER SEPARATOR

PASTEURİZATİON COMPACT SYSTEM 15.000 LT-H

Pasteurization Compact System 15.000 LT-H

BARIŞ TECHNOLOGİCAL INSTALLATİON

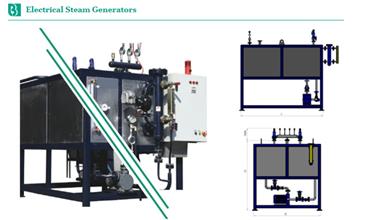

Small-sized, small-capacity ENERKON Electrical Steam Generators are perfect for industries that require quick, efficient, and high-quality steam in laboratories, hospitals..

MAZLUM STEEL PIPES

Potable Water Pipes with Epoxy Coating. Outside Diameter : 1016mm / Wall Thickness : 10mm / Pipe Length :13.50 Meters / Steel Grade : S355JR