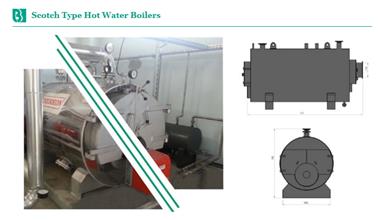

BARIŞ TECHNOLOGİCAL INSTALLATİON

Solid / liquid / gas and biogas fuel options, High efficiency, low thermal losses, Perfect design for optimal heat transfer and flue gas pressure drop, Low NOx formation with 3-pass design and large combustion chamber

ÖNER SEPARATOR

TECNOLOGICAL ONE TOUCH A DESING SOLUTION

TECNOLOGICAL ONE TOUCH A DESING SOLUTION

MAZLUM STEEL PIPES

The rock shoe prevents damage to the pile during pile driving in rocky ground.

Outside Diameter : 711,2mm

Wall Thickness : 14,2 mm

Per Pile Length : 25 Meters

MAZLUM STEEL PIPES

QUALITY CONTROL

XRAY and RT Test Line

Hydrostatic Tests

BARIŞ TECHNOLOGİCAL INSTALLATİON

COGENERATION - TRIGENERATION SYSTEMS

Cogeneration or combined heat and power (CHP) is the simultaneous production of electricity with the recovery and utilization of waste heat. Cogeneration is a highly efficient form of