Our ISIN PP-R Pipes carries the advantageous aspects of the plastic pipe industry such as; smooth, shiny, hygienic and easy installation. It is an indispensable

solution for hot water systems as opposed to indoor and cold galvanized pipes. PP-R Pipes are used safely in shopping mall, airport, municipality and public buildings, residence, villa, subway, school, hotel and stadium projects.

All kinds of PP-R Pipes and Fittings used for the stages of hot and cold water installations in buildings are

producing from the highest quality raw materials. PP-R raw material is divided into three classes in terms of heat, pressure and chemical durability. These are: Type-1, Type-2 and Type-3. Raw material PP-H (Polypropylene Homopolymer), Type-2,

Raw material PP-B (Polypropylene Blockcopolymer), Type-3, Raw material PP-R (Polypropylene Randomcopolymer), includes Type-1 PP-H. Type-3 raw material

has higher performance and better properties in terms of physical and chemical properties of Type-1 and Type-2 raw materials. The most important feature of this raw material in the PP-R pipe industry is its high resistance to heat and chemical hazards. The reason for the successful use of PP-R Pipes and Fittings in cold and hot water systems is due to the resistance of the raw material of PP-R. The monomer

structure of PP-R raw material creates a random chain and protects it. PP-R Pipe and Fittings It does not allow any biological material that produces the raw material of PP-R, it can be colored, and provides excellent properties in preserving the taste and smell of the fluid passing through it.

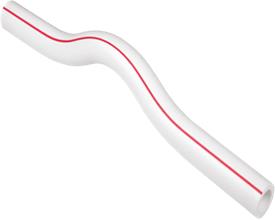

PP-R FIBER GLASS PIPES AND FITTINGS

Glass Fiber Composite Pipe consists of 3 layers. The inner and outer layers are made of polypropylene (PP-R), and the intermediate layer is composed of glass

fiber and PPR raw material.Glass Fiber Composite Pipe, which is formed by combining the advantages of straight pipes and foiled pipes, provides high

efficiency and usage advantages and eliminates many disadvantages such as shaving.

FEATURES

• Does not require shaving. Therefore, it provides faster assembly and application possibilities.

• There is no sweating and elongation problem.

• It can be used as an alternative to foiled pipes as it has an expansion coefficient close to the foiled pipes. Its working life is 50 years at 20 C and 20 bar pressure.

• Since they have a low expansion coefficient, they can be used in the temperature range

of -20 to 95 C. (However, insulation should be applied considering the

freezing point of the fluid in the pipe at minus degree.)

• It is resistant to freezing in cold weather. However, appropriate insulation

should be applied considering the freezing degree of the fluid in the pipe.

• It does not cause any change in the color, smell and taste of the water. It is environmentally friendly.

INSTALLATION

If the ambient temperature is below +5C, the heating time should be increased by 50%. This time is the time from the removal of the pipe and fitting from the welding threads to the joint. After the installation of the composite pipe installation is completed, the quality control of the installation must be carried out by applying the following test procedure. All valves in the installation are brought to the closed position. While the installation is being filled, the main valve is

slightly opened first. In order to avoid strong pressure pulses, the air is carefully taken from the highest and farthest usage area of the pipelines. While testing, the valve of each zone should be opened separately.

Step 1: The entire piping system in the building is subjected to a leak test for 30 minutes at 1.5 times the maximum prescribed pressure. Pressure drop and

leakage are observed between the 10th and 20th minutes. The pressure is raised again. During the 30-minute period, a pressure drop of more than 0.6 bar and leakage should not occur at any point.

Step 2: A pressure of 1.5 times is applied for 2 hours. This time, a pressure drop of more than 0.2 bar and leakage should not occur at any point of the installation.

If the pressure drops more than the values given above in the manometer

where the test is being monitored, there is a leak. Leaking pipeline should be checked and

replaced or re-tightened. All installations should be washed before starting to use. Lines that will not be used should be closed and drained against freezing.

SIGNIFICANT MATTERS IN PP-R COMPOSITE PIPES AND FITTINGS

At the end of the foil peeling process in PP-R pipes with aluminum foil, there should be absolutely no foil particles in the welding distance.For turns over 30º, a 45º

elbow should be used.Excessive tightening should be avoided in metal fitting applications, teflon tape should be used instead of hemp.Pipes should be cut perpendicular

to the pipe axis and with sharp pipe cutters.Dirty pipes and fittings should not be welded, deformed and cracked pipes and fittings should not be used.Pipes must be protected from all kinds of impact and impact.Conical threaded parts should not be used in the connections.The installation must be protected against the risk of freezing.If the installation will not be used after the test process, the water in the installation must be emptied against the risk of freezing.Welding should not be done if the Teflon on the threads is worn out or broken. (Teflon life is as long as 2-3 residential applications.)Welding waiting time should be observed, pipes and fittings should not be rotated during melting.Precautions should be taken against steam compression in gas water heater installations.Pipe and fittings should not be exposed to direct sunlight for a long time.PP-R raw material does not contain UV-resistance stabilizer. The maximum storage period is six months in the environment in contact with sunlight.After the installation is laid, the pipes and fittings in the sections outside the building should be isolated against UV rays and freezing.