Company : ATLAS DENIM TEXTILE

ATLAS DENIM TEXTILE

AtlasDenim has 260 000 𝑚2total area in Adana Organized Industrial Zone in Turkey, established in 2016 AtlasDenim offers expertise with wide range of high quality denim fabrics, fast delivery, and effective price policies we provide customer focused unrivalled products, services tailored to our clients’ specific needs and high customer satisfaction owing to our young and dynamic team AtlasDenim is reputed as one of the most technological and the highest quality denim fabric manufacturers producing beyond international standards by making no concessions to the human dignity, workers’ rights and safety, and the ecological sustainability.

For More Details : http://www.atlasdenim.com.tr/en/

Currently, with running 3 6 8 looms Picanol Optimax I, our company is one of the largest integrated textile corporations of Turkey Around 5 5 00 000 meters highest quality fabric in a month has been produced by our assembly lines with 98 quality rate in terms of denim fabric New 60 looms have been planted in the last quarter of 2021. Total looms number increased to 388 , our production capacity increased to around 6 million meters.

Our fabrics’ weight ranges between 4 5 15 oz Thanks to our new high tech yarn facility, we are able to produce more variations depending on our customers’ requests Our fabrics blends are mostly cotton, polyester, modal, dual core, rayon, viscose, tencel cottonpoly and elastane what is more, we are able to meet the orders from bamboo, jute, flax, and hemp.

ATLASDENIM is a proud member of ZDHC (Zero Discharge of Hazardous Chemicals), which has the mission to eliminate hazardous chemicals from the textile industry, and a proud member of SEDEX, which is a globally-recognized audit approach that assesses responsible supply chain activities, including labor rights, health & safety, the environment and business ethics.

OEKO-TEX® Standard 100, Class I for babies and toddlers – indicates every component of our fabric has been tested for harmful substances and therefore is proven to be harmless in human ecological terms and even the most sensitive skins. HIGG INDEX pioneered the assessment and measurement of our in-house production and supply chain environmental and social sustainability performance. The current assessment score is measured as 89! SLCP consists of Converged Assessment Framework (CAF) and SLCP Gateway, a web-based centralized repository for hosting and sharing of verified assessments. Further it enables redistribution of verified assessments to Accredited Host (AH), such as Fair Factory Clearinghouse (FFC), Higg Facility Social & Labor Module (Higg FSLM) and Inspectorio.

GOTS (Global Organic Textile Standards) – proves our fabric is made from organic fibers, and while producing, high-level environmental criteria along the entire organic textiles supply chain and requires compliance with social criteria have been fulfilled. GRS (Global Recycled Standard) – verifies our recycled content meets requirements for chain of custody, social and environmental practices and chemical restrictions. OCS (Organic Content Standards) “Organic 100” and “Organic Blended” – allows for transparent, consistent and comprehensive independent evaluation and verification of our organic material content. RCS (Recycled Claim Standards) “Recycled 100” and “Recycled Blended” – proves the presence of recycled material and quantity in our final recycled product.

BCI (Better Cotton Initiative) – shows our commitment and investment to more sustainable cotton production.

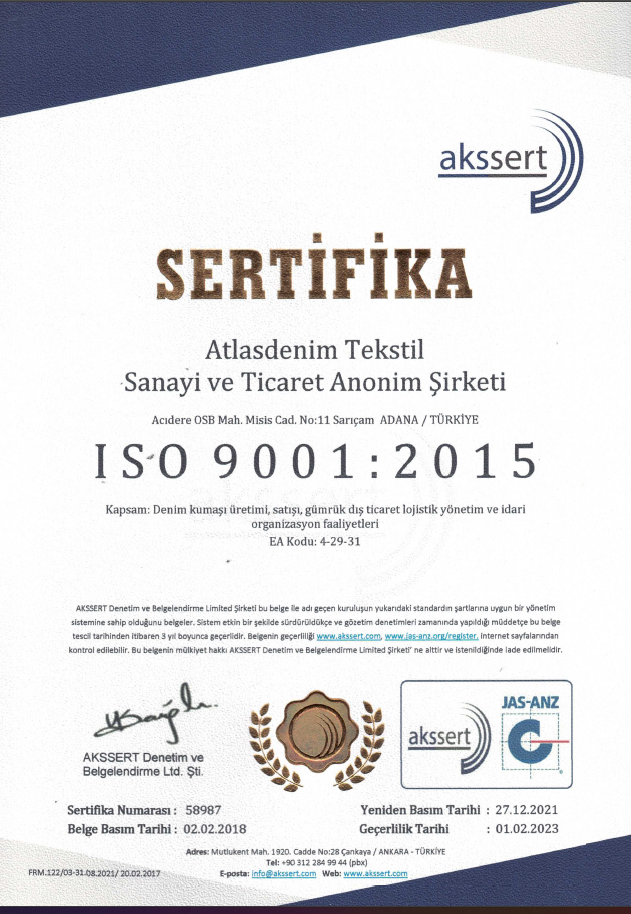

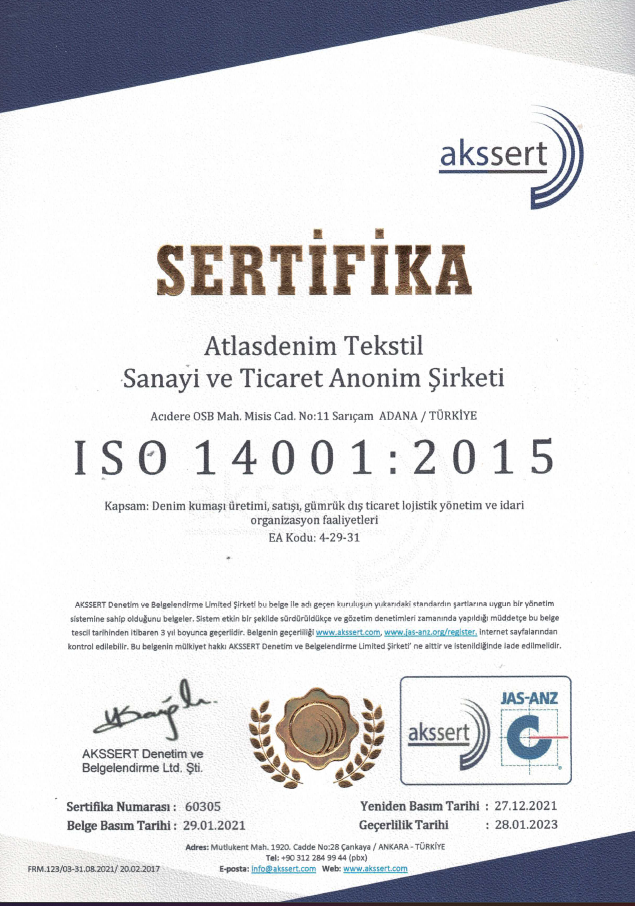

ISO 14001 – Environmental Management Standard

ISO 45001 – Occupational Health and Safety Standard

ISO 50001 – Energy Management Standard

ISO 9001 – Quality Management System Standard

COTTON POLYESTER BLEND FABRIC

- AtlasDenim has 260.000 square meters total area in Adana Organized Industrial Zone in Turkey, established in 2016.

- Currently, with running 388 looms Picanol Optimax I (acquired in 2018), our company is one of the largest integrated textile corporations of Turkey.

- Around 5.000.000 meters highest quality fabric in a month has been produced by our assembly lines with %98 quality rate in terms of denim fabric; moreover, we have numerous references from companies with excellent reputations in the world market.

- Our fabrics’ weight ranges between 4,5 – 15 oz. Thanks to our new high-tech yarn facility, we are able to produce more variations depending on our customers’ requests. Our fabrics blends are mostly cotton, polyester, modal, dual core, rayon, viscose, tencel, cottonpoly and elastane; what is more, we are able to meet the orders from bamboo, jute, flax, and hemp.

- AtlasDenim offers expertise with wide range of high-quality denim fabrics, fast delivery, and effective price policies; we provide customer-focused unrivalled products, services tailored to our clients’ specific needs and high customer satisfaction owing to our young and dynamic team.

DENIM FABRIC

- AtlasDenim has 260.000 square meters total area in Adana Organized Industrial Zone in Turkey, established in 2016.

- Currently, with running 388 looms Picanol Optimax I (acquired in 2018), our company is one of the largest integrated textile corporations of Turkey.

- Around 5.000.000 meters highest quality fabric in a month has been produced by our assembly lines with %98 quality rate in terms of denim fabric; moreover, we have numerous references from companies with excellent reputations in the world market.

- Our fabrics’ weight ranges between 4,5 – 15 oz. Thanks to our new high-tech yarn facility, we are able to produce more variations depending on our customers’ requests. Our fabrics blends are mostly cotton, polyester, modal, dual core, rayon, viscose, tencel, cottonpoly and elastane; what is more, we are able to meet the orders from bamboo, jute, flax, and hemp.

- AtlasDenim offers expertise with wide range of high-quality denim fabrics, fast delivery, and effective price policies; we provide customer-focused unrivalled products, services tailored to our clients’ specific needs and high customer satisfaction owing to our young and dynamic team.

DENIM FABRIC SUPPLIERS

AtlasDenim Tekstil Sanayi ve Ticaret Anonim Şirketi is in Adana Organized Industrial Zone operates on an area of 160.000 m2 within 120.000 m2 indoor and 40.000 m2 outdoor since 2016. Our company services with specialized, equipped, disciplined and professional staffs with the denim fabric sector.

POLYVISCOSE FABRIC

- AtlasDenim has 260.000 square meters total area in Adana Organized Industrial Zone in Turkey, established in 2016.

- Currently, with running 388 looms Picanol Optimax I (acquired in 2018), our company is one of the largest integrated textile corporations of Turkey.

- Around 5.000.000 meters highest quality fabric in a month has been produced by our assembly lines with %98 quality rate in terms of denim fabric; moreover, we have numerous references from companies with excellent reputations in the world market.

- Our fabrics’ weight ranges between 4,5 – 15 oz. Thanks to our new high-tech yarn facility, we are able to produce more variations depending on our customers’ requests. Our fabrics blends are mostly cotton, polyester, modal, dual core, rayon, viscose, tencel, cottonpoly and elastane; what is more, we are able to meet the orders from bamboo, jute, flax, and hemp.

- AtlasDenim offers expertise with wide range of high-quality denim fabrics, fast delivery, and effective price policies; we provide customer-focused unrivalled products, services tailored to our clients’ specific needs and high customer satisfaction owing to our young and dynamic team.

YARN PRODUCTION FACILITY

- AtlasDenim has 260.000 square meters total area in Adana Organized Industrial Zone in Turkey, established in 2016.

- Currently, with running 388 looms Picanol Optimax I (acquired in 2018), our company is one of the largest integrated textile corporations of Turkey.

- Around 5.000.000 meters highest quality fabric in a month has been produced by our assembly lines with %98 quality rate in terms of denim fabric; moreover, we have numerous references from companies with excellent reputations in the world market.

- Our fabrics’ weight ranges between 4,5 – 15 oz. Thanks to our new high-tech yarn facility, we are able to produce more variations depending on our customers’ requests. Our fabrics blends are mostly cotton, polyester, modal, dual core, rayon, viscose, tencel, cottonpoly and elastane; what is more, we are able to meet the orders from bamboo, jute, flax, and hemp.

- AtlasDenim offers expertise with wide range of high-quality denim fabrics, fast delivery, and effective price policies; we provide customer-focused unrivalled products, services tailored to our clients’ specific needs and high customer satisfaction owing to our young and dynamic team.

ISO 9001

ISO 14001

ISO 27001

ISO 45001

ISO 50001

Global Organic Textile Standard

Global Recycled Standard

Organic Content Standard

Recycled Claim Standard

OEKO-TEX

SUPPLIER TO ZERO

© 2021 AIP Export. All Rights Reserved. AOSB