Company : SCA METAL

SCA METAL

Our

company, which has partners with 30 years of experience in the iron and steel

industry, operates in an indoor areas of 5,000 m² in the Adana Organized

Industrial Zone. Its fields of activity include galvanized and painted sheet

trade and sandwich panel production for cold storage. Furthermore, we undertake

turnkey contracts for steel construction and cold storage.

Our

Vision

Global food loss and waste in order to reduce cold air

tank established the manufacture of complete solutions to the customer demands

and expectations and it has the aim to create added value, sectoral knowledge

and experience of effective team spirit designed with awareness, awareness in

international markets, which is one of the successful representatives of a

company is to position the country.

Our Mission

To be a company that keeps its promises to its

customers, can produce flexible solutions in its commercial relations, and can

supply goods at an affordable price.

For more detail: https://scametal.com.tr

Cold Room Doors

Casing:

It is produced in three different types as Panel Mounted, Plastic and Aluminum.

Wing

/ Thickness: Door wings are produced by injecting 40 (± 2) kg / m³ density

polyure-thane between two sheets without using any wood material. Door thicknesses

are 68 mm in cold storages and 92 mm in frozen preserving storages. There is a

heater (resistance) in the door frame of the frozen storage rooms that can be

easily changed when necessary.

Surface

Sheet: In standard productions, both sides of the wing are polyester sheet.

(POLY) In addition, PVC and CRNI can be made optionally and some standard

colors can be produced for PVC surfaces.

Lock

/ Hinge: Door locks are produced in accordance with the international standards

and can be opened from inside when the door is locked. The hinges used in the

manufacture of the doors are raiseable and adjustable.

Dimensions:

It can be made in maximum 1200 X 2000 mm net transition dimensions, and special

production can be made in smaller sizes upon request.

Cold Storage Devices

It is suitable for cold storage and facilities where room

temperature requirements are between (-5 ° C / + 5 ° C).

Thanks to these devices with Split and Industrial Type

options, you can keep your products stored in rooms and facilities of all sizes

at desired in-room temperatures, regardless of their size.

Split Type devices are easy to install and maintain thanks

to their small compact design. Hermetic, Semi Hermetic, Scroll types are

available.

Thanks to its Ready-to-Install Compact Designs; we offer to your

service our devices that allow for easy maintenance with quality equipment,

vibration-free operation and ultra-silent fan features.

Capacity

Cold Storage Range (-10 C / + 45 C): 0.74 kW ~ 93.7 kW

Compressor

TYPE: Semi Hermetic-Hermetic-Scroll

BRAND: Frascold / Bitzer / Dorin / Gea Bock / Tecumseh /

Copeland NOMINAL

POWER RANGE: 0.5 HP ~ 50 HP

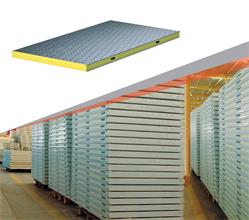

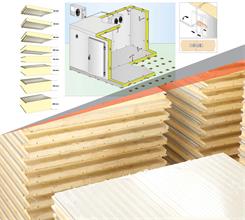

Cold Storage Panel

We produce our ceiling and

wall panels in 3 different ways in terms of surface types. POLY: Inner and

outer surfaces are 0.50 mm thick galvanized sheet, and RAL 9002 color

polyester-based paint is available on it.

PVC: Sheet thickness on the

inner and outer surfaces is 0.50 mm, and there is antibacterial PVC coating on

galvanize.

CR-NI: Sheet thickness on the

inner and outer surfaces is 0.50 mm, and there is 304 quality, 1st class

antibacterial PVC coating on galvanize.

CR-NI: Sheet thickness on the

inner and outer surfaces is 0.50 mm, and there is 304 quality, 1st class

antibacterial PVC coating on galvanize.

Corrugated Sandwich Panels

• The surfaces of the panels are

manufactured as corrugated (waterway).

• Panels are equipped with lock system

(pulling and locking) and they are connected to each other with a male-female

fitting detail.

• Panels are produced with polyurethane

filling between two sheets at a density of 40 (±2) kg / m³.

• In order to ensure full sealing

feature, wall panels are produced in a special lug (notched) structure.

• Panels are 1110 mm wide as standard

and can be produced up to a length of 12.00 meters.

• All panel surfaces are shipped with a

protective film to be disassembled after assembly.

• Panels are produced with a thickness

of 50-80-100-120-150-180-200 mm.

Cooling Devices

It is one of the components that are needed in cold air

stores and vary according to room temperature, volume and tonnage capacity of

the stored product. Considering the capaci-ties;

• Split

Type

• Industrial

Type

• Central

Systems

Considering the in-room temperatures, they are classified as

follows;

• Cold

Storage Devices

• Frozen

Storage Devices

• Shock

Devices

Floor Panels

Frozen Storage Devices

It is suitable for cold storage and facilities where room

temperature requirements are between (-18 ° C / - 25 ° C).

Thanks to these devices with Split and Industrial Type

options, they can be used in rooms and facilities of all sizes, regardless of

their size.

Split Type devices are easy to install and maintain thanks

to their small compact design. Hermetic, Semi Hermetic, Scroll types are

available.

Thanks to its Ready-to-Install Compact Designs; we offer to

your service our devices that allow for easy maintenance with quality

equipment, vibration-free operation and ultra-silent fan features.

Capacity

Frozen Storage Range (-30ºC/+45ºC) : 1.10 kW ~ 36.00 kW

Compressor

TYPE: Semi Hermetic-Hermetic-Scroll

BRAND: Frascold / Bitzer / Dorin / Gea Bock / Tecumseh /

Copeland NOMINAL

POWER RANGE: 1.5 HP ~ 50 HP

Monorail Doors

It is widely produced for meat integrated facilities. It

works with the principle of shifting to the right and left at the processing

and freezing transition points.

We can manufacture monorail doors as hinged and sliding. In

accordance with the standards, we provide production using special materials

and we guarantee use for many years.

Casing: The outer case is special PVC and the inner case is

aluminum.

Wing / Thickness: Door wings are produced by injecting 40 (±

2) kg / m³ density polyure-thane between two sheets without using any wood

material. Door thicknesses are 92 mm in cold storages and 120 mm in frozen

preserving storages. There is a heater (resistance) in the door frame of the

frozen storage rooms that can be easily changed when necessary. Surface Sheet:

In standard productions, both sides of the wing are polyester sheet. (POLY) In

addition, PVC and CRNI can be made optionally and some standard colors can be

produced for PVC surfaces.

Suspension Hardware / Security: Carrier rail, wheels, handles

and necessary accessories are made of composite material and stainless steel in

accordance with the international standards. The doors can be easily opened

from the inside for security purposes, and preferably an alarm-warning system

can be added.

Dimensions: It is not in standard sizes, but can be produced

in special sizes upon request.

Panel Accessories&Assembly Profiles

Assembly accessories; are accessories in various sizes and

features designed to adjust the floor seating arrangement of the panels in cold

room installation, to eliminate the visual pollution that may occur in the edge

and corner joints, to provide hygiene and to allow installation of ceiling

panels. Furthermore; these are the profiles used in the assembly of floor, wall

and ceiling panels.

Panel assembly/mounting accessories can be PVC or polyester

coated galvanized sheet or CR-NI depending on the panel surfaces used.

Assembly Accessories vary according to the panel surfaces

used and the physical and technical features of the cold storage. These

accessories are;

• Floor (U)

Accessory

• Internal

and External Corner Accessories, Hygienic Accessories.

• Ceiling

Hanger Profiles and Ceiling Hanger Apparatus.

Single / Double Wing Bar Doors

• It can be

mounted on panel and wall, and its door wings can be opened 90 degrees in both

directions and can remain always open when necessary.

• Wing

thickness of bar doors which are generally used in services and operating

passa-ges is 40 mm and they are manufactured by injection of polyurethane with

a density of 40(±2) kg/m³ between two sheets without using any wooden material,

both as with and without window.

• In standard

productions, both sides of the wing are polyester sheet. (POLY) Doors can be

produced optionally by using PVC and CRNI materials, with two surfaces being

different or the two surfaces being the same. Production can be made in some

standard colors for PVC surfaces.

• Aluminum

material is used in the casings and moldings of the single wing bar doors, and

it can be produced in special sizes starting from 700 x 1700 mm net passage

dimensions.

• Aluminum

material is used in the casings and moldings of the double wing bar doors, and

it can be produced in special sizes starting from 1200 x 2000 mm net passage

dimen-sions.

• Preferably,

a protective strip and stainless steel surface sheet can be placed on the lower

surfaces of the doors.

Sliding Doors

Casing: It is produced in two different types as Plastic and

Aluminum. There are special plastic additions in order to prevent the formation

of heat bridges in our doors, and aluminum material is used for the inner

moldings.

Wing / Thickness: Door wings are produced by injecting 40 (±

2) kg / m³ density polyure-thane between two sheets without using any wood

material. Door thicknesses; in cold storages

Door thicknesses are 92 mm in cold storages and 120 mm in

frozen preserving storages. There is a heater (resistance) in the door frame of

the frozen storage rooms that can be easily changed when necessary.

Surface Sheet: In standard productions, both sides of the

wing are polyester sheet. (POLY) In addition, PVC and CRNI can be made

optionally and some standard colors can be produced for PVC surfaces.

Suspension Hardware / Security: Carrier rail, wheels,

handles and necessary accessories are made of composite material and stainless

steel in accordance with the international standards. The doors can be easily

opened from the inside for security purposes, and preferably an alarm-warning

system can be added.

Dimensions: It is not in standard sizes, but can be produced

in special sizes upon request.

© 2021 AIP Export. All Rights Reserved. AOSB