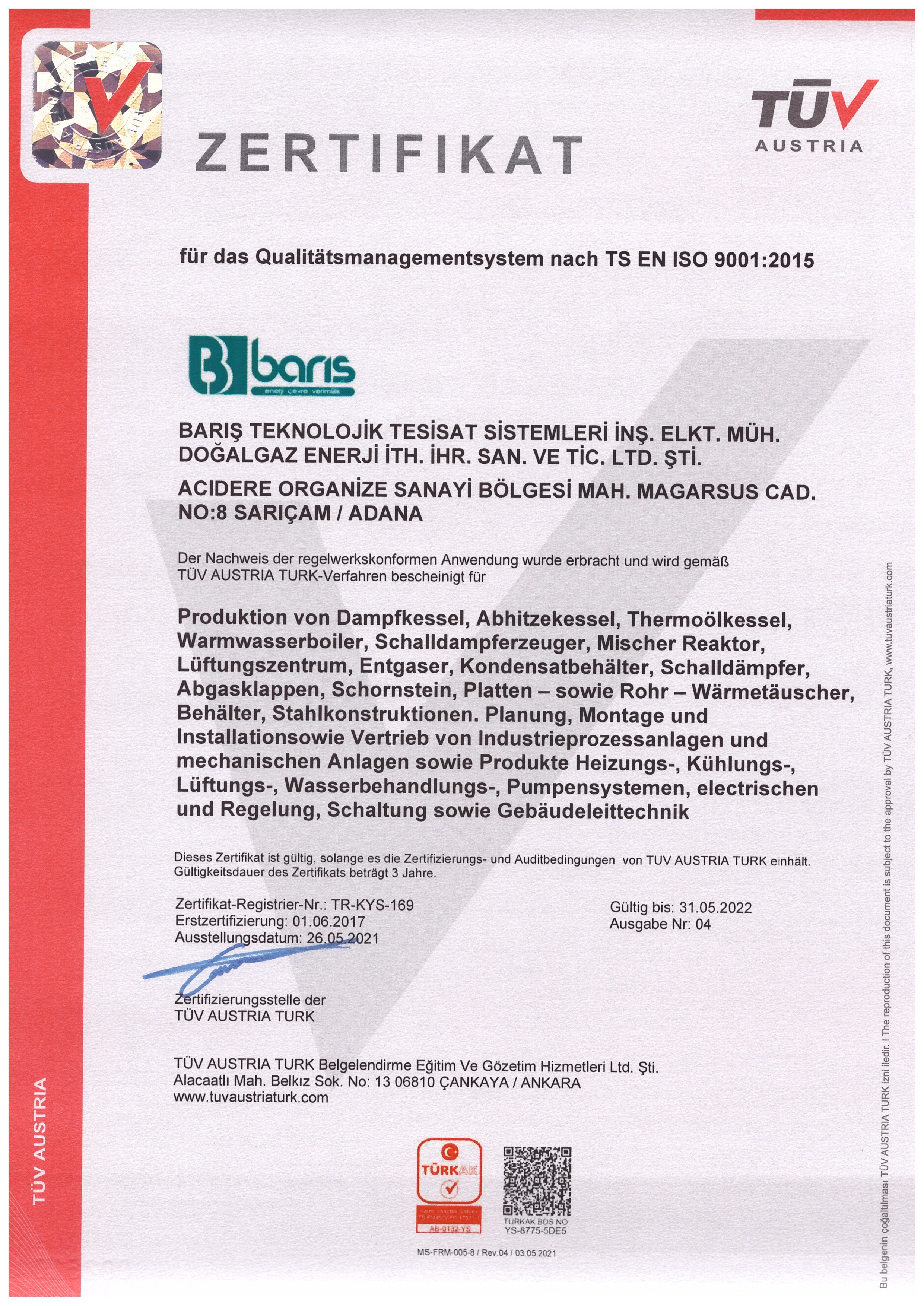

Company : Barış Technological Installation

Barış Technological Installation

Established in 1997, and with an executive board consisting of experienced engineers, the company operates in the areas of developing energy conservation oriented (waste) heat recovery projects, on-site manufacturing of (waste) heat recovery devices required for the projects, and undertaking of these turn-key projects.

The company has reached the present day by studiously preserving its principles of honest, reliable and quality services, and by making no concessions to its principle of "unconditional customer satisfaction".

By following the latest developments in the world and by making use of these developments and innovations in our country, our primary purpose is to provide investors in the sectors of electromechanic installation and energy with services parallel to today's technology and perspective.

Our Productions;

Thermal Boilers, Scot Type Hot Water Boilers, Thermal Oil Boilers, Electrical Steam Generators, Indirect Steam Generators, Steam Generators, Direct Water Heater, Industrial Stack, Economizers and Air Preheaters, Custom designed Containers, Thermal Degasser Systems, Cogeneration Trigeneration Systems, Industrial Fans And Filiters, Steam Generators.

More Details : http://www.barismuhendislik.com.tr/en/

COGENERATION - TRIGENERATION SYSTEMS

Cogeneration or combined heat and power (CHP) is the simultaneous production of electricity with the recovery and utilization of waste heat. Cogeneration is a highly efficient form of energy conversion and it can achieve primary energy savings of approximately 40% by compared to the separate purchase of electricity from the national electricity grid and a gas boiler for onsite heating. Combined heat and power plants are typically embedded close to the end-user and therefore help reduce transportation and distribution losses. Trigeneration is also the simultaneous production of electricity with heating and cooling loads.

Advantages of Cogeneration

- It is possible to get overall efficiencies up to 90%.

- Thanks to better efficiency and clean fuel, cogeneration is the most environmentally-friendly energy solution.

- It serves a high-quality power supply to the owner.

- The plant may not be affected in case of any failure thanks to single connection to the grid. (Parallel mod)

- Better efficiency due to no transportation losses.

- Owners do not have to pay taxes on illegal usages.

- Reactive energy and compensation costs decrease.

- Smaller capacity backup generator.

- Reduced dependence on foreign fuel due to high efficiencies.

Application Fields

- Hospitals

- Shopping Malls, Hotels,

- Residence

- Olympic Facilities

- Government Buildings

- Airports

- Treatment Plants

- Industrial Plants, Factories

PDF Catalog for Product

CUSTOM DESIGNED CONTAINERS

Customer Benefits

- Length is possible up to 12 mt (40 ‘)

- Easy transportation is available because of the compact frame

- Sound insulation is possible at the desired level

- Thermal insulation is possible at the desired level

- It is resistant to outdoor conditions

- Two or more service doors are available

- Ventilation, lighting, and fire system are up to request

- Certified production BV, T. Loyd) is up to request

Application Fields

- Cogeneration systems

- Diesel generator systems

- Compressor stations

- Modular heating or cooling stations

- Control panel and power rooms

PDF Catalog for Product

DIRECT WATER HEATER

Product Features

- Direct hot water production from cold water

- Design and production for oil and gas fuels

- Completely hot galvanized or stainess steel production

- Seconder heating system is not necessary (Steam, Hot water)

- Thermal compensation due to large water volume

Application Fields

- Worksites

- Hospitals

- Hotels

- Laundries

- Low-temperature heat consuming plants

PDF Catalog for Product

ECONOMIZERS AND AIR PREHEATERS

Design and Fabrication

- Engineering according to fuel and application specifications

- Perfect design for optimal heat transfer and water/flue gas pressure drop

- Delivery with all auxiliary equipments (Optional)

- Smoketube and finned watertube constructions

- Design and production for oil-gas and solid fuel-fired systems

- Stainless steel and condensing types are available

- CE certifications in accordance with EN 12952 ve 2014/68/EU (Optional)

Benefits of Economizer Applications

- Each 21 C Temperature drop in stack gases means %1 efficiency increase of boiler

- Over %100 efficiencies can be achieved using condensing economizers which recovers latent heat of water vapor in exhaust gases

- Preheating of boiler feed water increases boiler life by preventing thermal shocks

- Emission release to atmosphere could be less with decreased fuel consumption

- Combustion air can be preheated to recover stack waste heat as well

Some Application Fields

- Boiler feedwater or combustion air preheating

- Process or heating water production

- Additional energy recovery in cogeneration stacks

- Heat recovery from marine engine stacks

- Heat recovery from furnace stacks

PDF Catalog for Product

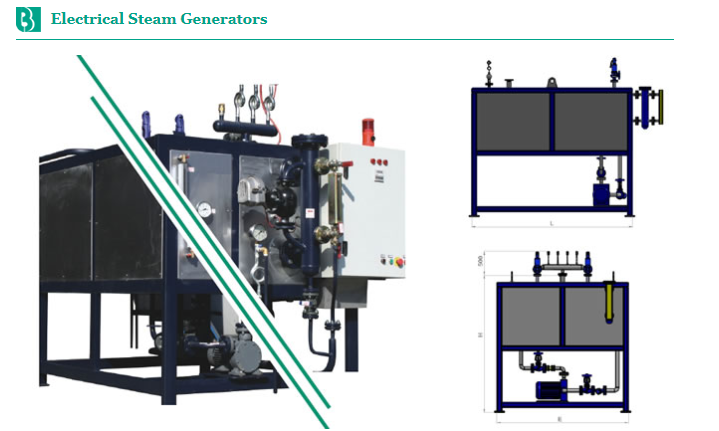

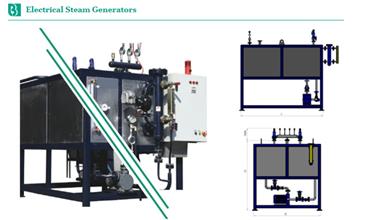

ELECTRICAL STEAM GENERATORS

Specifications

- Easy installation

- Designed according to heavy operating conditions

- No fuel system

- No smoke discharge system

- Packaged delivery with condensate tank, pump unit, water softening unit, and auxiliaries

- Less space requirement

- Short switching time

- Operates automatically and safely

- Stainless steel production is available

- CE marking according to 2014/68/EU is possible

Material

Bodyshell: EN 10028 / 2 - Boiler steel

Heating elements: Seamless stainless tube

Insulation: 100 mm Rockwool with aluminum plate outer casing

INDIRECT STEAM GENERATORS

Indirect steam generators can be used instead of a steam boiler in plants where a sufficient heating system exists.

Indirect Steam Generator Specifications

- Less space requirement due to packaged construction

- Low-pressure fluctuations due to large steam and water volume

- No water carry-over due to large steaming surface

- Economical investment because of no stack and fuel line requirements

- Stainless steel production is available for hygienic steam

Heating Fluids for Indirect Steam

- Thermal Oil

- Hot Water

- Steam

- Waste oil or other hot process fluids

PDF Catalog for Product

INDUSTRIAL STACK

- Industrial stacks suitable for solid, liquid, and gaseous fuels

- Design and manufacturing in accordance with TS EN 13084

- Custom designed solutions for special site and flue conditions

- Easy erection due to modular design

- Wide production range in accordance with fuel, temperature, and dimension

Design and Fabrication

- Solid / liquid / gas and biogas fuel options

- Calculations in accordance with Standards

- Perfect design for low heat loss and flue gas pressure drop

- Modular Design

- Exhaust temperatures up to 800 C

- Low sound emission possibility with integrated silencer possible

- High-corrosion strength with stainless steel inliner

Application Fields

- Cogeneration

- Trigeneration

- Boiler Stacks

- Furnace Stacks

- Cement Mills

- Steel Industry

- Petrochemical Industry

- Biogas Plants

Material

Inner Shell: 1.404 or 1.4301 Stainless steel

Outer Shell (If applied): EN 10025-S 235 JRG2 Mild steel

Insulation : Rockwool or glasswool

Outer Casing: AISI430 Stainless steel or aluminum plate

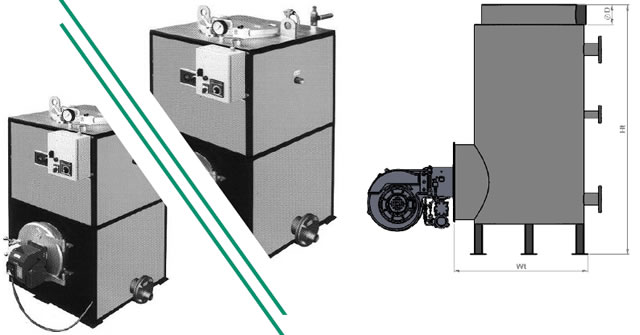

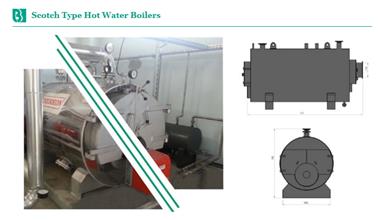

SCOTCH TYPE HOT WATER BOILERS

Design and Fabrication

- Solid / liquid / gas and biogas fuel options

- High efficiency, low thermal losses

- Perfect design for optimal heat transfer and flue gas pressure drop

- Low NOx formation with 3-pass design and large combustion chamber

- Less sweeping loss due to large water content

- The easily reachable combustion chamber and smoke tubes for maintenance

- NDT controls and hydrostatic testings

- Additional efficiency increase with turbulator application (Optional)

- Three passes, high efficient hot water boilers up to 10 Mcal/h thermal output

- CE certifications in accordance with TS 377-EN 12953 and 2014/68/EU

Material

Body shell and tube plates: EN 10028 / 2 - P265 GH, P295 GH, P355 GH Boiler steel

Boiler steel smoke tubes: EN 10216 / 2 - P235 GH Seamless boiler tube

Insulation: 100 mm Rockwool with AISI430 or aluminum plate outer casing

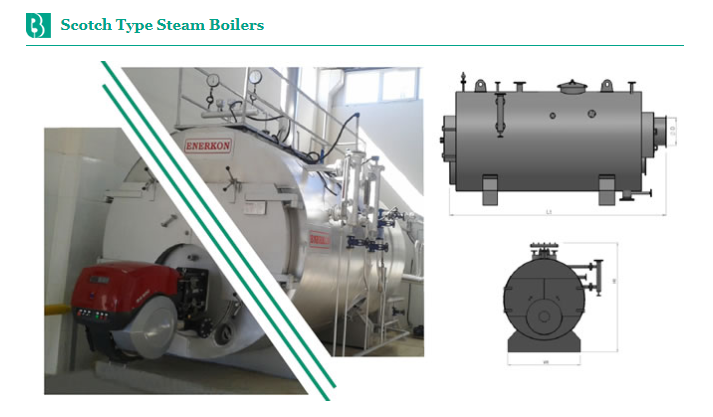

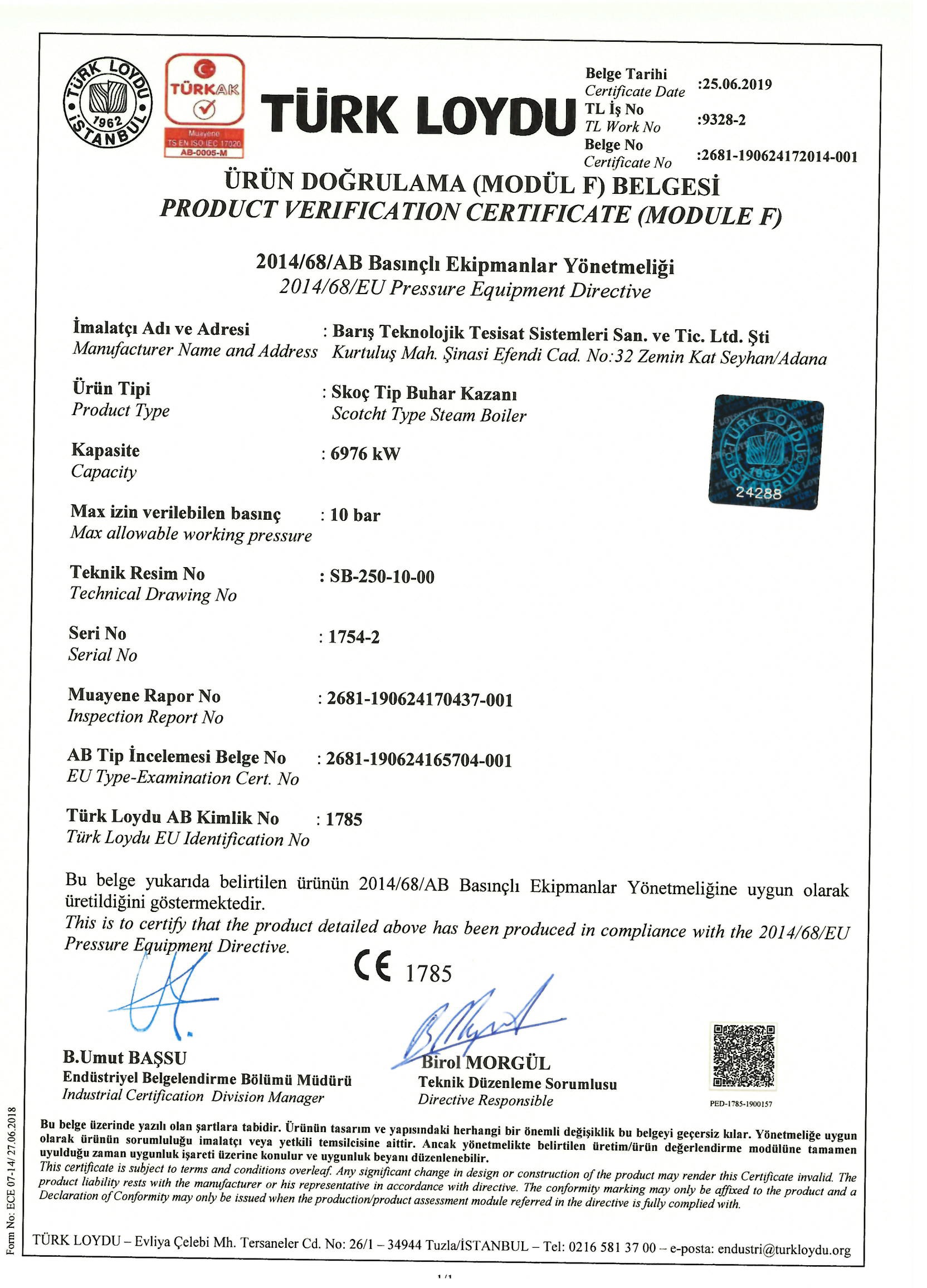

SCOTCH TYPE STEAM BOILERS

Design and Fabrication

- Solid / liquid / gas and biogas fuel options

- High efficiency, low thermal losses

- Perfect design for optimal heat transfer and flue gas pressure drop

- Low NOx formation with 3-pass design and large combustion chamber

- Less sweeping loss due to large water content

- Easy reachable combustion chamber and smoke tubes for maintenance

- NDT controls and hydrostatic testings

- Boiler efficiency up to %95 with additional economizer

- Three Pass, High Efficient Steam Boilers up to 20 t/h Steam Capacity

- CE Certifications in Accordance with TS 377-EN12953 and 2014/68/EU

Material

Body shell and tube plates: EN 10028 / 2 - P265 GH, P295 GH, P355 GH boiler steel

Smoke tubes: EN 10216 / 2 - P235 GH Seamless boiler tube

Insulation: 100 mm rockwool with AISI430 or aluminium plate outer casing

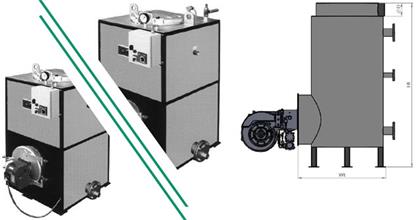

SMOKE TUBE AND WATER TUBE STEAM GENERATORS

- Ideal solution for plants that need low capacity and quick steam production.

- Three pass, high efficient steam generators up to 5 t/h steam capacity.

- Smoke tube and water tube constructions.

- CE certifications in accordance with EN 1295/53 and PED 2014/68/EU.

Design and Fabrication

- Liquid/gas and biogas-like fuel options.

- High efficiency, low thermal loss.

- Perfect design for optimal heat transfer and flue gas pressure drop.

- Low NOx formation with 3-pass design and large combustion chamber.

- Dome Steam separator for dry steam in case of smoke tube const.

- The easily reachable combustion chamber and tubes for maintenance.

- NDT controls and hydrostatic testings.

- Boiler efficiency up to 95% with additional economizer.

Material

Bodyshell and tube plates: EN 10028 / 2 - P265 GH, P295 GH, P355 GH Boiler Steel

Smoke and water tubes:EN 10216 / 2 - P235 GH Seamless boiler tube

Insulation: 100 mm Rockwool covered by AISI430 or aluminum plate

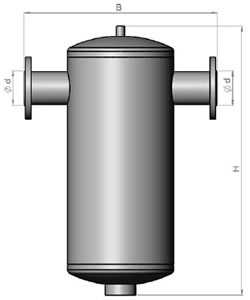

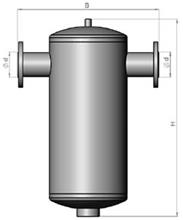

STEAM SEPARATORS

Steam Separator Specifications

- Provides efficient and economical solutions for processes that need dry steam

- Provides efficient separation with centrifugal effect

- Needs no maintenance due to having no moving part

- Withstands unfavorable conditions and water hammer

- Completely welded fabrication by certificated welders

- Optionally stainless steel material is possible

Material

Body shell and dished heads: EN 10028 / 2 - P265 GH, P295 GH, P355 GH

Tubes: EN 10216 / 2 - P235 GH Seamless boiler tube

THERMAL DEAERATOR SYSTEMS

Deaeration is the process of removing the dissolved oxygen from the boiler feedwater. Additionally, in the deaeration process, the CO2 is also removed. Removal of these two gases is important in boiler feed water as both of the gases promote corrosion in the boiler or steam system.

An additional benefit of a deaerator is the high water feeding temperature to the boiler, so the risk of low-temperature corrosion on the smoke side is decreased and thermal shocks are eliminated in the boiler.

- Oxygen removal up to 7 ppb (0,005 cc/l)

- Complete CO2 removal

- Up to 50 tph water capacity

- Standard 10 minutes of storage capacity

- Long boiler and installation life

PDF Catalog for Product

THERMAL OIL BOILERS

Design and Fabrication

- Solid / liquid / gas and biogas fuel options

- High efficiency, low thermal losses

- Perfect design for optimal heat transfer and oil/flue gas pressure drop

- Low NOx formation with 3-pass design and large combustion chamber

- NDT controls and hydrostatic testings

- Delivery with all auxiliary equipments (Optional)

- Capacities up to 10.000.000 kcal/h and o Temperatures up to 320 C at Atmospheric Pressure

- Thermal oil systems solutions based on electrical heating

- CE certifications in accordance with EN 12952 and 2014/68/EU

- System design in accordance with DIN 4754

Advantages Of Thermal Oil System

- Elevated temperatures at atmospheric pressure

- No consumption of heat transfer fluid and chemicals

- No corrosion risk due to heat transfer fluid

- No risk of freezing in the winter

- Reach operating conditions in a short time

Material

Bodyshell: EN 10028 / 2 - P265 GH Boiler steel

Coil tubes: EN 10216 / 2 - P235 GH Seamless boiler tube

Insulation: 100 mm Rockwool with AISI430 or aluminum plate outer casing

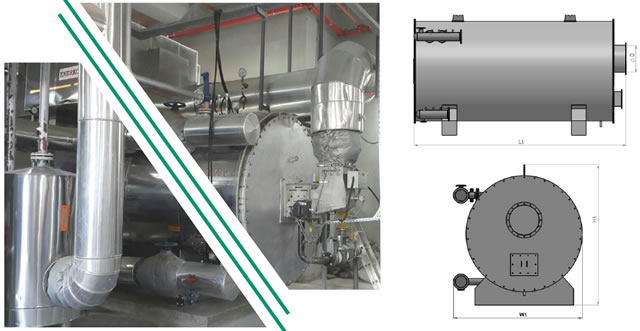

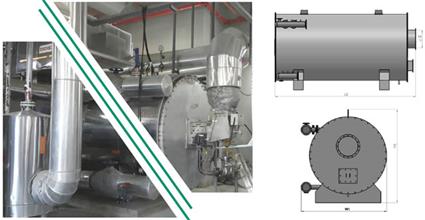

WASTE HEAT RECOVERY BOILERS

- Waste heat boilers for hot water, Steam, Superheated steam, Thermal oil, and hot air production

- Smoketube and watertube constructions

- Custom designed solutions according to waste heat and site conditions

- High efficient heat production with supplementary firing

- Combined systems operating with exhaust gases and register burner

- Packaged cogeneration units in the containerized system

Design and Fabrication

- Solid / liquid / gas and biogas fuel options

- High efficiency, low thermal losses

- Perfect design for optimal heat transfer and flue gas pressure drop

- Single and multi-pass design

- Natural or forced circulation

- Superheated steam production possible

- NDT controls and hydrostatic testings

Application Fields

- Cogeneration and Trigeneration

- Oven Stacks

- Marine Engine Stacks

- Cement Mills

- Steel Industry

- Petrochemical Industry

- Biogas Plants

What is Produced With

- Electric Energy With ORC Cycle

- Proses Steam

- Hot Water

- Thermal Oil

- Hot Air

- Cooling with Absorption Chiller

Material

Body shell, drum, and tube plates:EN 10028 / 2 - P265 GH, P295 GH, P355 GH Boiler steel

Smoketubes and watertubes:EN 10216 / 2 - P235 GH Seamless boiler tube

Insulation:100 mm Rockwool with AISI430 or aluminum plate outer casing

© 2021 AIP Export. All Rights Reserved. AOSB